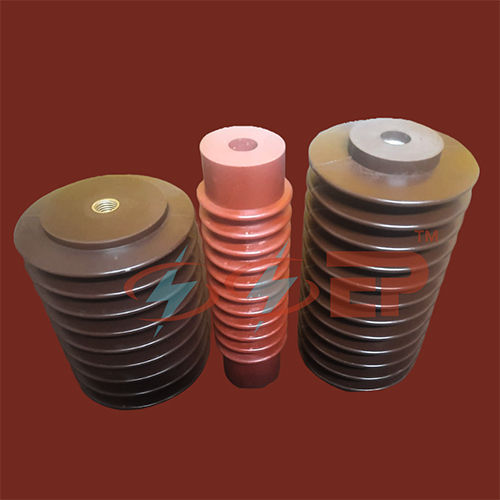

Epoxy Insulator

Price 1500 INR/ Unit

Epoxy Insulator Specification

- Size

- 35 mm

- Product Type

- Epoxy Insulator

- Material

- Stainless Steel / Iron

- Thickness

- 0.1 mm to 2 mm Micrometers (um)

- Application

- Transformer

- Color

- Red

- Phase

- 3 Phase

About Epoxy Insulator

"Epoxy Insulator 45" likely refers to a specific type of epoxy insulating material with a Shore hardness rating of 45. Heres an overview of what this might entail:

1. Epoxy Insulator Epoxy insulators are electrical insulation components made from epoxy resin, a thermosetting polymer known for its excellent electrical insulation properties, mechanical strength, and thermal stability.

2. Shore Hardness Shore hardness is a measure of the resistance of a material to indentation or penetration by a harder object. The Shore hardness scale is commonly used for elastomers and polymers. A Shore hardness of 45 indicates a material with moderate hardness, falling in the mid-range of the Shore hardness scale.

3. Application Epoxy insulators with a Shore hardness of 45 may be suitable for various electrical insulation applications where a balance of flexibility and rigidity is required. They could be used as insulating spacers, supports, or barriers in electrical equipment such as transformers, circuit breakers, switchgear, and motors.

4. Properties Epoxy insulators with a Shore hardness of 45 are likely to exhibit properties such as:

- Good electrical insulation: Effective at preventing electrical conduction and breakdown.

- Mechanical strength: Able to withstand mechanical stress and load-bearing requirements.

- Thermal stability: Resistant to heat and temperature variations encountered in electrical applications.

- Chemical resistance: Able to withstand exposure to oils, solvents, and other chemicals commonly found in industrial environments.

5. Manufacturing Epoxy insulators with specific hardness ratings are typically manufactured by mixing epoxy resin with curing agents and additives, followed by molding or casting into the desired shape. The curing process involves applying heat or chemical catalysts to promote cross-linking and solidification of the resin.

6. Selection When selecting epoxy insulators, its essential to consider factors such as:

- Electrical requirements: Voltage, current, and insulation resistance.

- Mechanical requirements: Load-bearing capacity, dimensional stability, and impact resistance.

- Environmental conditions: Temperature, humidity, and exposure to chemicals or UV radiation.

- Regulatory compliance: Ensuring compliance with relevant industry standards and safety regulations.

7. Installation Proper installation of epoxy insulators involves ensuring adequate clearance, spacing, and support to maintain electrical insulation and mechanical integrity. They should be securely mounted or attached to prevent movement or damage during operation.

Overall, epoxy insulators with a Shore hardness of 45 offer a balance of electrical insulation and mechanical strength, making them suitable for various applications in electrical equipment where moderate hardness and flexibility are required. Its essential to consult with manufacturers or suppliers to ensure that the specific epoxy insulator meets the requirements of the intended application.

Precision Engineering for Transformer Applications

Our Epoxy Insulator is crafted specifically for high-performance transformer use. Engineered with precise dimensions and superior materials, it ensures long-lasting, stable insulation in demanding 3-phase systems. The red color not only distinguishes the insulator for safety and maintenance but also complements modern electrical standards. Each unit undergoes rigorous testing to comply with industry requirements, guaranteeing consistent quality from Indias leading supplier.

Customization and Versatility

We offer Epoxy Insulators in a range of thicknesses from 0.1 mm up to 2 mm micrometers, allowing flexibility for a variety of transformer configurations. Whether your project demands stainless steel or iron construction, our products are tailored to meet specific operational and environmental challenges. Trust our proven manufacturing process for reliable and adaptable solutions.

FAQs of Epoxy Insulator:

Q: How are epoxy insulators used in transformer applications?

A: Epoxy insulators are installed in transformers to isolate and protect electrical conductors, preventing short circuits and ensuring safe 3-phase power distribution. The insulating properties of epoxy, combined with the durability of stainless steel or iron, make them ideal for high-voltage environments.Q: What materials are available for these epoxy insulators?

A: Our epoxy insulators are available with a core of either stainless steel or iron, both coated with high-grade epoxy resin. These materials are selected for their strength, conductivity control, and resistance to environmental stress.Q: When should I use a 0.1 mm versus a 2 mm thick insulator?

A: The choice of thickness depends on the insulation needs and spatial constraints of your specific transformer application. Thinner insulators (0.1 mm) are ideal for compact assemblies with lower voltage, while thicker options (up to 2 mm) offer enhanced protection for higher voltage systems.Q: Where are these epoxy insulators manufactured and supplied from?

A: Our epoxy insulators are manufactured and supplied from India, ensuring prompt delivery and support for clients domestically and internationally through our established distribution network.Q: What is the process for manufacturing your epoxy insulators?

A: Our epoxy insulators are produced through a meticulous process that involves molding high-grade epoxy resin over stainless steel or iron cores. The insulators undergo precise machining and rigorous quality checks to meet industry standards for electrical safety and durability.Q: How do the color and design of the insulator benefit users?

A: The bright red color of our epoxy insulators enhances visibility for maintenance and inspection purposes, reducing risks during installation and operation. The compact 35 mm size and tailored thicknesses provide versatility for various transformer configurations.Q: What are the primary benefits of using your epoxy insulators in transformers?

A: The main advantages include excellent electrical insulation, superior mechanical strength, resistance to moisture and heat, and suitability for both indoor and outdoor transformer setups. These qualities contribute to extended equipment lifespan and operational reliability.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Epoxy Insulator Category

Epoxy Insulator 33KV

Price 1500 INR / Number

Minimum Order Quantity : 06 Units

Rated Voltage : 33Kv. Volt (V)

Application : Electrical

Product Type : Epoxy Resin Cast

Color : Red or Chocolate Brown

Epoxy Insulator 11KV

Price 390 INR / Unit

Minimum Order Quantity : 25

Rated Voltage : 11Kv Volt (V)

Application : Electrical

Product Type : Epoxy Resin Cast

Color : Red or Chocolate Brown

Send Inquiry

Send Inquiry